Have you ever tightened an exhaust manifold bolt, only to wonder, “Did I do it right?” You’re not alone! Many car enthusiasts and DIY mechanics struggle with getting the torque just right. Too loose, and you risk leaks and performance issues. Too tight, and you might snap a bolt—ouch! In this guide, I’ll break down everything you need to know about torque specifications for exhaust manifold bolts in the simplest way possible. Whether you’re fixing a leak or installing a new manifold, I’ve got you covered. Let’s dive in and make sure you never second-guess a bolt again!

Understanding the Importance of Proper Torque for Exhaust Manifold Bolts

Why Torque Matters

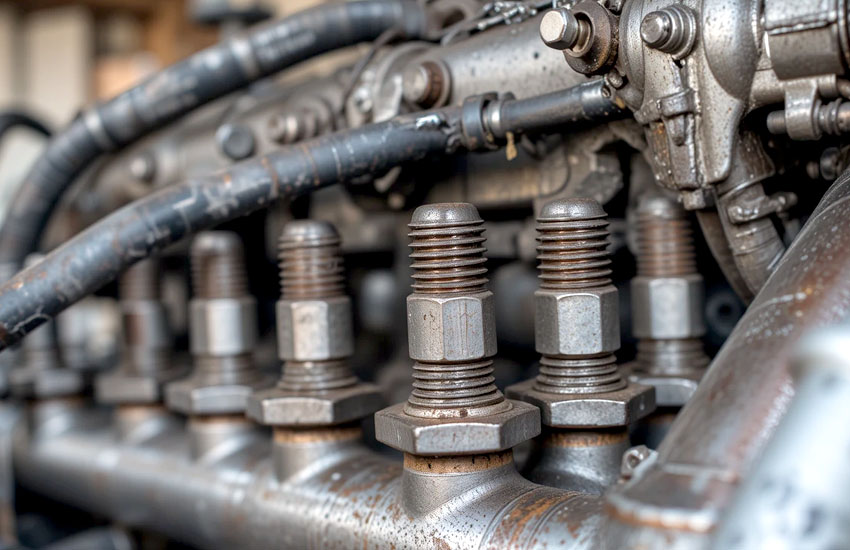

When tightening exhaust manifold bolts, using the correct torque is crucial. The exhaust manifold is responsible for collecting engine exhaust gases and directing them into the exhaust system. If the bolts are not tightened properly, it can cause a variety of issues, including:

- Exhaust Leaks – Loose bolts create gaps, allowing gases to escape. This can lead to poor engine performance and loud hissing noises.

- Warping and Cracking – If you overtighten the bolts, you can warp the manifold or even crack it over time due to excessive stress.

- Broken Bolts – Applying too much force can snap a bolt, making removal a nightmare.

- Check Engine Light – Exhaust leaks can trigger the oxygen sensors, causing the check engine light to turn on.

What Is Torque, and Why Does It Matter?

Torque is simply the amount of twisting force applied to a bolt. It is measured in foot-pounds (ft-lb) or Newton-meters (Nm). Car manufacturers specify torque values to ensure that bolts are neither too loose nor too tight. Following these values keeps the exhaust manifold securely fastened without damage.

How Incorrect Torque Affects Your Engine

Incorrect torque settings can lead to serious problems. A leak at the exhaust manifold can allow unburned fuel to enter the system, affecting emissions and fuel efficiency. It can also let air in, causing incorrect readings for the oxygen sensors. This results in poor combustion, leading to reduced power and increased fuel consumption.

Common Myths About Exhaust Manifold Torque

- “Tighter is always better!” – False! Over-tightening can cause damage, especially with aluminum cylinder heads.

- “You don’t need a torque wrench!” – Wrong. Guessing torque values by hand is unreliable and can lead to uneven pressure.

- “Torque specs don’t change between engines!” – Incorrect. Different engines require different torque values due to material differences.

By understanding why torque matters, you can avoid costly mistakes and ensure your exhaust system works as intended. Now, let’s look at the recommended torque values for different vehicles.

Recommended Torque Specifications for Different Vehicle Models

Where to Find the Correct Torque Specifications

Each vehicle has a specific torque specification for exhaust manifold bolts. The best places to find these values are:

- Your vehicle’s repair manual – This provides the manufacturer’s exact torque specs.

- OEM websites – Many automakers publish repair information online.

- Trusted automotive forums – Enthusiasts often share real-world torque specs and tips.

Example Torque Values for Popular Cars

Here are some common torque specifications for various vehicles:

- Honda Civic (2006-2015): 23-25 ft-lb

- Ford F-150 (5.4L V8, 2004-2010): 18-22 ft-lb

- Chevy Silverado 1500 (5.3L V8, 2000-2020): 18-25 ft-lb

- Toyota Camry (2.5L, 2010-2020): 20-23 ft-lb

Always double-check the exact torque for your specific engine to avoid errors.

Factors That Affect Torque Specifications

Several factors can influence the correct torque value:

- Material Type – Aluminum cylinder heads require lower torque than cast iron.

- Thread Condition – Dirty or corroded threads may affect torque readings.

- Lubrication – Some bolts require anti-seize compound, affecting torque values.

Now that you know the right torque specs, let’s go over how to properly tighten the bolts.

How to Accurately Torque Exhaust Manifold Bolts: Step-by-Step Guide

Tools You’ll Need

Before starting, gather the right tools:

- Torque wrench (for precise tightening)

- Socket set with extensions

- Anti-seize compound (for preventing corrosion)

- Penetrating oil (for rusty bolts)

Step 1: Prepare the Surface

Ensure the exhaust manifold and cylinder head mating surfaces are clean. Use a wire brush or sandpaper to remove old gasket material and debris. A clean surface helps create a proper seal.

Step 2: Hand-Tighten the Bolts

Before using a torque wrench, start by threading all bolts in by hand. This prevents cross-threading, which can cause major problems.

Step 3: Use a Torque Wrench

Set your torque wrench to the manufacturer’s recommended torque. Begin tightening in a crisscross pattern to ensure even pressure distribution. Tightening one side fully before the other can lead to warping.

Step 4: Tighten in Stages

Instead of applying full torque at once, tighten the bolts in increments. For example, if the final torque is 22 ft-lb, start with 10 ft-lb, then move to 15 ft-lb, and finally reach 22 ft-lb. This prevents sudden stress on the manifold.

Step 5: Double-Check Your Work

After all bolts are torqued, go over them once more to ensure none have loosened. Start the engine and check for any exhaust leaks. A hissing sound indicates a leak, requiring bolt re-tightening.

By following these steps, you can ensure a secure and leak-free exhaust manifold installation.

Frequently Asked Questions

Is it necessary to use a torque wrench?

Yes! A torque wrench ensures you don’t over-tighten or under-tighten the bolts, preventing leaks and damage.

Can I reuse old exhaust manifold bolts?

It depends. Some manufacturers recommend replacing them, especially if they have stretched or corroded.

Do I need anti-seize on exhaust manifold bolts?

In most cases, yes. It prevents corrosion and makes future removal easier. However, check your manufacturer’s recommendations.

Can I tighten the bolts without a specific torque value?

It’s not recommended. Guessing can lead to uneven tightening, leaks, or broken bolts. Always follow the specs.

Is it okay to overtighten for extra security?

No! Over-tightening can warp the manifold, break bolts, or crack cylinder heads. Stick to the recommended torque.

Do I need to retorque the bolts after driving?

Some vehicles require rechecking after a few heat cycles. Always refer to your manual.

Can a loose exhaust manifold cause engine problems?

Yes! It can cause exhaust leaks, performance issues, and even trigger the check engine light.

Is there a difference in torque specs for aftermarket manifolds?

Yes! Aftermarket parts may have different material properties, so always check the included instructions.

I hope this guide helped you understand why torque specifications for exhaust manifold bolts are so important! Proper tightening prevents leaks, damage, and ensures your engine runs smoothly. Whether you’re a beginner or an experienced mechanic, following the right steps will save you time and trouble. Now, grab that torque wrench and get to work!